Ground rods: The Complete Guide

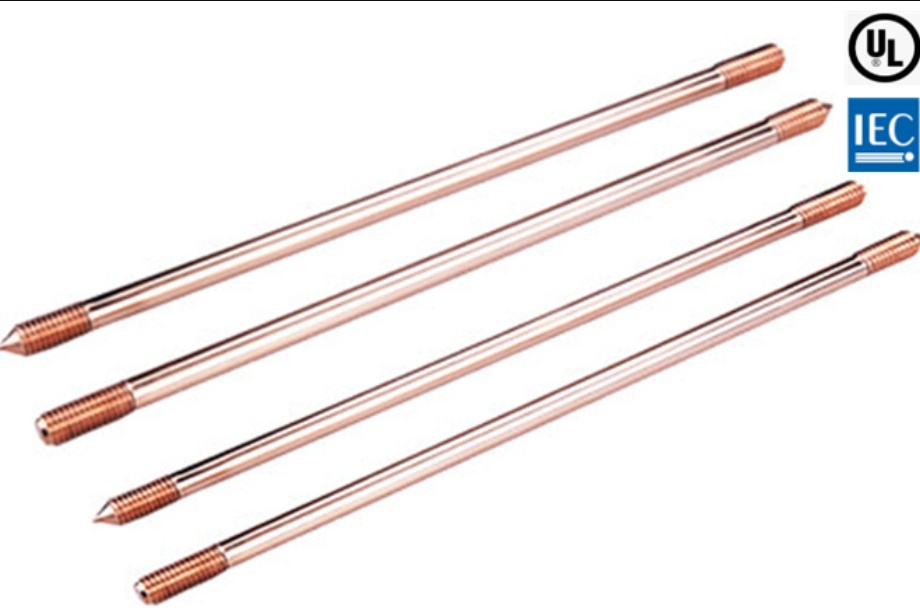

Grounding rods are essential safety components in electrical systems, designed to reduce grounding resistance and enhance the reliability of grounding systems. The copper-bonded steel grounding rods produced by Hebei Changdi Lightning Protection Technology Co., Ltd., feature a high-purity copper layer of 99.9% purity bonded with a high-quality carbon structural steel core, creating a composite material with exceptional strength. These grounding rods are specifically engineered for vertical grounding applications and exhibit excellent tensile strength and ductility, ensuring no cracks in the copper layer even when bent at a 90-degree angle. Moreover, they have undergone rigorous electrical-corrosion performance tests to guarantee that the resistance value increase remains within safe limits after simulating fault current discharge. Hebei Changdi Lightning Protection Technology Co., Ltd. offers a rapid delivery time and high-quality after-sales service, ensuring customers receive the necessary support promptly. Opt for the copper-bonded steel grounding rods from Hebei Changdi for a higher level of safety assurance in your electrical systems.

- Chapter 1: What Are Ground rods?

- Chapter 2: Main Uses Of Ground rods

- Chapter 3: Types Of Ground rods

- Chapter 4: Technical Specification Of Ground rods

- Chapter 5: The Process Of Making A Ground rods

- Chapter 6:How To Install Ground rods

- Chapter 7:Packaging and shipping

- Chapter 8:Frequently Asked Questions (FAQs)

- Chapter 9:Contact Us

- Chapter 10:Conclusion

What are ground rods?

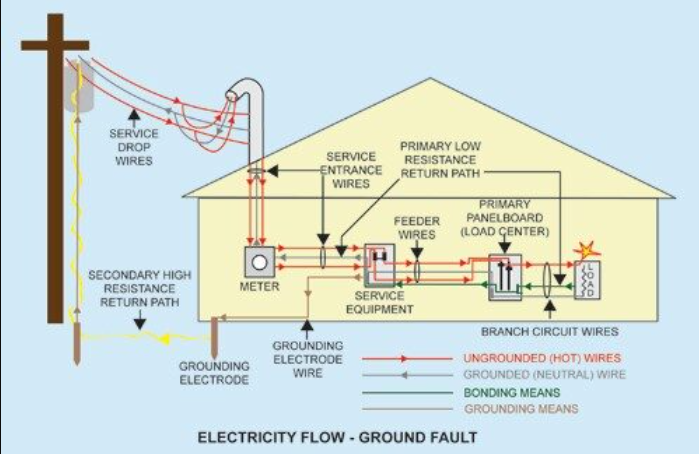

Ground rods, essential for establishing a safe and effective grounding system, are metallic rods that serve as a direct connection to the earth. They are crucial for diverting electrical currents into the ground, safeguarding structures and electrical systems from potential damage caused by lightning, power surges, and other electrical anomalies. Hebei Changdi Lightning Protection Technology Co., Ltd. specializes in manufacturing copper-bonded steel earth rods, which are composite materials with a steel core made from high-quality carbon structural steel and an outer layer of copper with a remarkable purity of 99.9%. These rods are engineered for vertical grounding applications, designed to minimize grounding resistance and bolster the security of the grounding system.

The technical specifications of Hebei Changdi’s ground rods include a tensile strength suitable for both vertical and horizontal grounding, a customizable copper thickness that ensures flexibility and durability, and a robust bond between the copper layer and the steel core that remains intact even under significant stress or when bent at sharp angles. Moreover, these rods are subjected to rigorous electrical-corrosion performance tests to ensure that they maintain their integrity and functionality over time, with resistance value growth kept well within acceptable limits.

Main Uses of guound rods

Ground rods, integral to electrical safety, serve a variety of purposes within the realm of power systems and lightning protection. Hebei Changdi Lightning Protection Technology Co., Ltd. manufactures copper-bonded steel earth rods that are predominantly utilized as vertical grounding electrodes in grounding systems. These rods are engineered to minimize grounding resistance, thereby enhancing the overall safety and reliability of the system. They are commonly used to provide a direct, low-resistance path to the earth for fault currents, protecting electrical installations from voltage surges that can occur due to lightning strikes or other electrical faults. Additionally, ground rods are crucial in stabilizing voltage levels and preventing electrical interference, which is particularly important for sensitive equipment. They are also used in telecommunication systems to maintain signal integrity and to ensure the safety of individuals in the event of an electrical fault. The robust construction of Hebei Changdi’s ground rods, with a high-purity copper layer bonded to a carbon structural steel core, makes them suitable for a range of applications where dependable grounding is essential.

Types of ground rod

Ground rods, essential for grounding systems, come in various types to cater to different applications and installation requirements. Hebei Changdi Lightning Protection Technology Co., Ltd. specializes in manufacturing a specific type of ground rod known as copper-bonded steel earth rods. These rods are single-piece composites, featuring a high-purity copper layer of 99.9% purity bonded to a high-quality carbon structural steel core. This design offers a high bonding force and ensures superior electrical conductivity, making them suitable for both vertical and horizontal grounding applications.

The copper-bonded steel earth rods from Hebei Changdi are designed to reduce grounding resistance and improve the safety of the grounding system. They are available in a range of tensile strengths, copper thicknesses, and can be customized to meet specific project needs. These rods are also tested for their plasticity, bondability, and electrical-corrosion performance to ensure they meet or exceed industry standards such as IEEE837, IEC62561-2, and UL467.

In addition to the copper-bonded steel type, other common types of ground rods include solid copper rods, galvanized steel rods, and stainless steel rods. Each type has its own advantages and is chosen based on factors such as corrosion resistance, tensile strength, and cost-effectiveness. Regardless of the type, the primary purpose of a ground rod is to provide a reliable path for electrical current to flow into the ground, thereby safeguarding electrical systems and protecting people from potential electrical hazards.

Technical specification of ground rod

Hebei Changdi Lightning Protection Technology Co., Ltd. produces copper-bonded steel earth rods that are designed to meet the highest standards of electrical grounding. These rods are a testament to the company’s commitment to quality, offering a range of technical specifications that ensure their performance and reliability in various grounding applications.

The copper-bonded steel earth rods feature a tensile strength that ranges from 350-770 MPa for vertical grounding and 290-510 MPa for horizontal grounding, providing robust support against the forces encountered during installation and service. The copper layer, which is crucial for electrical conductivity, has a thickness that can be customized between 0.254mm to 0.8mm, allowing for flexibility to suit different project requirements.

The copper layer’s plasticity is such that when the rod is bent at a 90-degree angle, it does not crack, ensuring the integrity of the grounding system. Moreover, the bondability of the copper layer is tested rigorously; when the rod is clamped and the copper layer is hammered to expose the steel core, the remaining copper and steel parts maintain their bond, with no exfoliation visible to the naked eye.

Electrical-corrosion performance is another key specification, with the rods undergoing simulated fault current release tests. Post-testing, the final resistance value growth rate does not exceed 50% of the initial resistance value, and each test step’s resistance growth rate is capped at 15%, ensuring the rods’ surface remains free from cracks, pits, and bubbling defects.

These specifications are verified through performance testing that aligns with international standards such as IEEE837, IEC62561-2, and UL467, using the advanced testing equipment at the Sunlight experimental center. Hebei Changdi’s focus on precision and quality control ensures that every ground rod delivered is a product of the highest caliber, ready to serve as a critical component in grounding systems worldwide.

Quality compliance – ISO 9001

Hebei Changdi Lightning Protection Technology Co., Ltd. is committed to delivering products that not only meet but exceed industry standards, including the prestigious ISO 9001 quality management certification. This international benchmark ensures that every aspect of the company’s operations, from design and development to production and customer service, adheres to a strict set of guidelines aimed at enhancing customer satisfaction and product quality.

The ISO 9001 certification underscores Hebei Changdi’s dedication to continuous improvement and a robust quality management system. It reflects the company’s meticulous approach to product development, as evidenced by their copper-bonded steel earth rods. These rods are manufactured with a copper layer of 99.9% purity, bonded to a high-quality carbon structural steel core, and are designed to provide superior grounding solutions with high bonding force and reduced resistance.

The company’s adherence to ISO 9001 is evident in their comprehensive testing protocols, which include mechanical, electrical, and corrosion testing to ensure each ground rod meets the technical parameters outlined in international standards like IEEE837, IEC62561-2, and UL467. This commitment to quality is further reinforced by their after-sale service promise, where any product quality issues are addressed by their sales and technical engineers within 24 hours.

By maintaining ISO 9001 compliance, Hebei Changdi Lightning Protection Technology Co., Ltd. positions itself as a reliable partner for customers seeking high-quality grounding solutions, backed by a company-wide commitment to excellence and customer satisfaction.

The process of making ground rods

At Hebei Changdi Lightning Protection Technology Co., Ltd., the production of copper-bonded steel earth rods involves a meticulous process that ensures each rod is a high-quality grounding conductor. The process begins with selecting high-quality carbon structural steel for the core, which is known for its strength and durability. This steel core is then encased in a layer of copper with a purity of 99.9%, creating a composite material that combines the electrical conductivity of copper with the structural integrity of steel.

The copper layer is applied to the steel core using a bonding process that ensures a high bonding force between the two materials. This bond is critical for the rod’s performance as a grounding electrode, as it must withstand the forces applied during installation and resist separation under stress. The copper thickness can be customized, ranging from 0.254mm to 0.8mm, allowing for the production of rods that meet various grounding requirements.

Throughout the manufacturing process, the rods undergo a series of tests to ensure they meet the technical parameters set by international standards such as IEC and UL. This includes testing for tensile strength, plasticity of the copper layer, and copper layer bondability. The rods are also subjected to electrical-corrosion performance tests, which simulate fault current release to ensure the resistance value growth rate remains within acceptable limits after the test.

The commitment to quality is evident in every step of the process, from the selection of materials to the final testing and quality control measures. Hebei Changdi’s ground rods are not just manufactured; they are crafted with precision and care to provide reliable grounding solutions that enhance the safety and performance of electrical systems worldwide.

How to install ground rods?

The installation of ground rods, such as those manufactured by Hebei Changdi Lightning Protection Technology Co., Ltd., is a critical process that ensures the safety and effectiveness of a grounding system. While the specific installation process can vary based on the environment and the grounding system’s requirements, the following steps provide a general overview:

- Site Preparation: Choose a suitable location for the ground rod where the soil is free from rocks and other obstructions. The location should also be away from areas prone to flooding.

- Rod Preparation: Before installing, ensure the copper-bonded steel ground rod from Hebei Changdi is free from any damage and is clean. The rod should have a tensile strength suitable for vertical or horizontal grounding, depending on the application.

- Drilling or Driving: For a copper-bonded steel rod, you may use a rod driver or a hammer to drive it into the ground. Alternatively, for rocky or hard soil, an auger or drilling device may be necessary to create a hole for the rod.

- Clamping: Once the rod is in place, secure it using a clamp or a grounding rod anchor to prevent it from shifting over time.

- Backfilling: After the rod is firmly in place, backfill the hole with soil. It’s often recommended to use a backfill compound that enhances conductivity around the rod.

- Connecting the Electrode: Attach the grounding electrode to the electrical system using a suitable grounding wire or conductor. Ensure the connection is secure and corrosion-resistant.

- Testing: After installation, test the grounding system to verify that the resistance is within the acceptable range as per the local codes and standards.

- Maintenance: Periodically check the ground rod for any signs of corrosion or movement and maintain it accordingly.

Hebei Changdi Lightning Protection Technology Co., Ltd.’s commitment to quality ensures that their copper-bonded steel earth rods are designed to be durable and reliable, making the installation process more straightforward and the end result a safe and effective grounding system.

Packaging and shipping

Frequently Asked Questions (FAQs)

[wpforms id=”335″ title=”true”]

Conclusion

Hebei Changdi Lightning Protection Technology Co., Ltd. stands out as a reliable manufacturer of high-quality copper-bonded steel ground rods, designed to enhance the safety and efficiency of grounding systems worldwide. Their products are crafted with meticulous attention to detail, ensuring compliance with stringent technical parameters and international standards such as IEC and UL. With a focus on customization and a commitment to quality that extends from production through after-sale service, Hebei Changdi provides more than just grounding rods—they offer peace of mind. Their promise of a 15-workday lead time and a 24-hour response to any quality concerns underscores their dedication to customer satisfaction and service excellence. As a testament to their reliability, Hebei Changdi’s ground rods are the preferred choice for professionals seeking robust and dependable grounding solutions.